|

| OO Scale | N Scale | G Scale | Z Scale | HO Scale | Slot Cars & R⁄C |

| |||||||

|

|||||||

| Home Page | |||||||

| BUY GIFT VOUCHERS | |||||||

| Products | |||||||

| Latest News | |||||||

| RIGHT LINES | |||||||

| Bargains | |||||||

| Downloads | |||||||

| Events | |||||||

| Careers & Jobs | |||||||

| Carriage Services | |||||||

| About Us | |||||||

| Contact Us | |||||||

| Pay Us A Visit | |||||||

| Meet The Staff | |||||||

| Links | |||||||

| SHOPPING BASKET |

Your shopping basket is empty. To add an item, click the "Buy" button

| YOUR ACCOUNT | ||

|

||||

|

||||

| Prodigy Advance Digital System |

||||

| Cased Controllers |

||||

| Panel Mount Controllers |

||||

| Walkabout Controllers |

||||

| Modules & Transformers |

||||

| Scenics & Accessories |

||||

| Wiring & Electrical Components |

||||

| Tiny Signs | ||||

| Tools | ||||

|

||||

| O Scale | Wargaming | Architectural | Narrow Gauge | Tools+ | ||

BIG INTERVIEW - Lyndon Davies

STUART JORDAN talks to Lyndon Davies, CEO of Oxford.

Lyndon Davies (right) outside the Oxford factory in China.

Stuart Jordan: Oxford Diecast has been in business over 20 years, what changes have you seen in the industry in that time?

Lyndon Davies: It is difficult to isolate the answer to Oxford as I am approaching nearly 40 years in the business, which spans Mettoy, Corgi and Oxford. So in terms of that timespan, I choose these four:

The decline of UK manufacturing hurts the most. The hardest time was when we made the decision to close the last large scale manufacturing of diecast vehicles in South Wales in the year 2000.

The decline of major brands - a sensitive subject to discuss, but there has been a change. Oxford has always been an engineering based company, it is at our heart and what provides us with the determination to introduce new items each year. We were the former manufacturing arm of Corgi Toys - twenty years ago all of the Oxford employees originated form Corgi Engineering. For many European companies the brand comes first, the ‘subject matter’ second and the engineering third. I totally disagree as the ‘subject matter’ comes first, the engineering is second and the brand comes third. So the industry has become marketing led, not engineering led. I choke when I listen to some of the rubbish I hear. I believe that all key employees of diecast companies should spend three months in a factory for their work experience.

The closeness to market has meant that manufacturers have become so much closer to their customers. At 16 in Mettoys we relied heavily on toy shows to get orders. Back in the 70’s you would attend the London Toy Fair, and if the retailers didn’t place orders then they were likely to lose out. Equally new products could be shut out of general distribution on the whim of a buyer. Today, we can, if we want skip over these channels. However good wholesalers and retailers are a key part of the distribution process, so a balance in how this is handled is so essential.

Finaly, the engineering advances has meant that the time getting a product to market has decreased, it took a year back in the 70’s. Today, give me a subject and the motivation and I could get it to market in 6 months.

Network Rail Ford Transit Connect, a recent release in OO Scale from Oxford Diecast.

SJ: The Oxford Diecast range is expanding every month with new items being released. What inspires the specific vehicles and/or liveries that you produce? Is it market research, personal preference, or a bit of both?

LD: We have a good team of people, but I don’t believe in drawn out processes. Adrienne (Oxford Diecast Product Manager) and I spend one day each year running through the ranges. We then debate, agree and disagree on the tooling that will be introduced. It can be quite tense as there will always be disagreements. The decision making is drawn from our gut-instinct and listening to the people who buy our products, and the information fed to us. Every employee at Oxford has to face the frontline, at events and shows held throughout the UK and overseas. We have already agreed our 2017 tooling range and the liveries are being finalised, we have even scanned 4 of the vehicles. We won’t always get it right, but if we did I think it would be a bit boring.

SJ: Your ranges correspond directly to model railway scales, including the relatively new HO American range; do you see yourself primarily as part of the model railway industry, or the collectable model industry?

LD: That sounds like a marketing question. I am sure it is unprofessional of me to say, but I haven’t got a clue. Oxford produces affordable diecast products – that is essentially it. I point you back to the roots of our company – Mettoy - ‘Big Trev’ would say we make what the customer is ordering. We have a statement of intent and that is well documented.

Mr Bean's Mini, one of the best-selling Oxford Diecast items.

SJ: In 2009 you released your first diecast aircraft in 1/72 scale, was this due to customer demand or something you were interested in yourself?

LD: Customer Requests. Adrienne and I reviewed the feedback and decided that there was a need to produce an aircraft range.

SJ: What does 2016 hold for Oxford Diecast?

LD: Further releases of items in all of the Oxford Ranges in all scales. New licence additions, including Rolls Royce and JCB.

SJ: The much publicised OO Scale Oxford Rail range is well on the way, with the first wagon releases practically selling out straight away in August. Why did you decide to move into ready-to-run Model Railways?

LD: My grandfather was an engine driver – that is all I know. He died in 1915 and my father was orphaned. My father died when I was very young. My brothers and I were given green diecast steam locos by someone who lived in the Welsh Valleys as a memory of our grandfather – who this was we don’t know. So we decided to move into Railways because it is in my blood.

SJ: Were you pleased with the response to the build up to the Oxford Rail announcement? You had a lot of people guessing and generated a lot of interest on internet forums.

LD: Yes, I was surprised at the guessing. The Adams is in manufacturing as we speak, but I decided that I wanted to be closer to launch on our next loco, before releasing any information. So it is fully tooled, we have first off shots and we will update everyone shortly.

An engineering sample of the Oxford Rail Adams Radial.

SJ: What inspired the first choice of locomotive, the Adams Radial?

LD: Just reading about the history of the loco and the changes that took place over the many years it ran, and of course the engineering requirement of the different boilers, frames, chimneys, et cetera!

SJ: What new manufacturing techniques, if any, were used to produce the Oxford Rail Range?

LD: We haven’t used any new techniques, we didn’t even scan the Adams in preservation. We just worked from the drawings. It's always better as the preserved items are often so different to the original

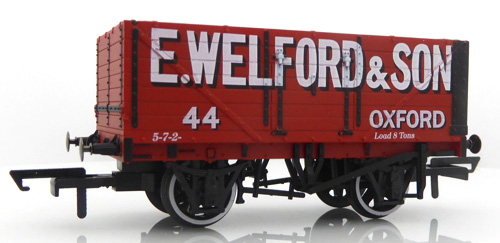

One of the first Oxford Rail releases, a 7-Plank Mineral Wagon. More versions are on their way!

SJ: Are you able to tell us what new Oxford Rail items are in the pipeline?

LD: No – why announce items so early – announce them when they are close to market!

SJ: Thank you for your time Lyndon.

To see the full Oxford Diecast range CLICK HERE

To see the full Oxford Rail range CLICK HERE

|

We are always looking to make improvements to our website to try and improve the quality of your visit. We would welcome your feedback and suggestions, so please do not hesitate to e-mail our webmaster with your comments. Alternatively call us on 01903 884488.

Home Cookies Privacy Statement Terms & Conditions Site Map Site Guide

WEEE Regulations Glossary Careers & Jobs

Tel – +44 (0) 1903 884488 Fax – +44 (0) 1903 884377 E-Mail us – click here

Gaugemaster.com is a trading name of Gaugemaster Controls Ltd.

Registered in England No. 2714470, Registered office:

Gaugemaster House, Ford Road

Arundel, West Sussex, BN18 0BN, United Kingdom

VAT Reg. No. 587 8089 71

Copyright © 2003-2014 Gaugemaster Controls Ltd. All Rights Reserved.